The goal of a mechanical screw press is simple: put pressure on oilseeds, drain as much oil as possible, and keep the solids in the barrel until discharge. The slotted barrel design allows for the efficient phase separation of liquid from solid and can be applied to an excess of 100 different materials.

But what happens when, unexpectedly, a stream of solids starts extruding out from between the barrel bars where the oil should be flowing? Your simple screw press may not be so simple anymore. You have a problem, and it likely comes down to your barrel spacing.

Incorrect barrel spacing, which can happen if oil processors assume a one-size-fits-all approach to setting up spacers, can be an issue that results in significant production loss over time. While there are general standards that can be used to set up a barrel initially, the fact is that oilseed pressing deals with highly variable raw materials, and the barrel spacing will need to be adjusted based on the machine’s response to a material.

Spacing during each stage in the process

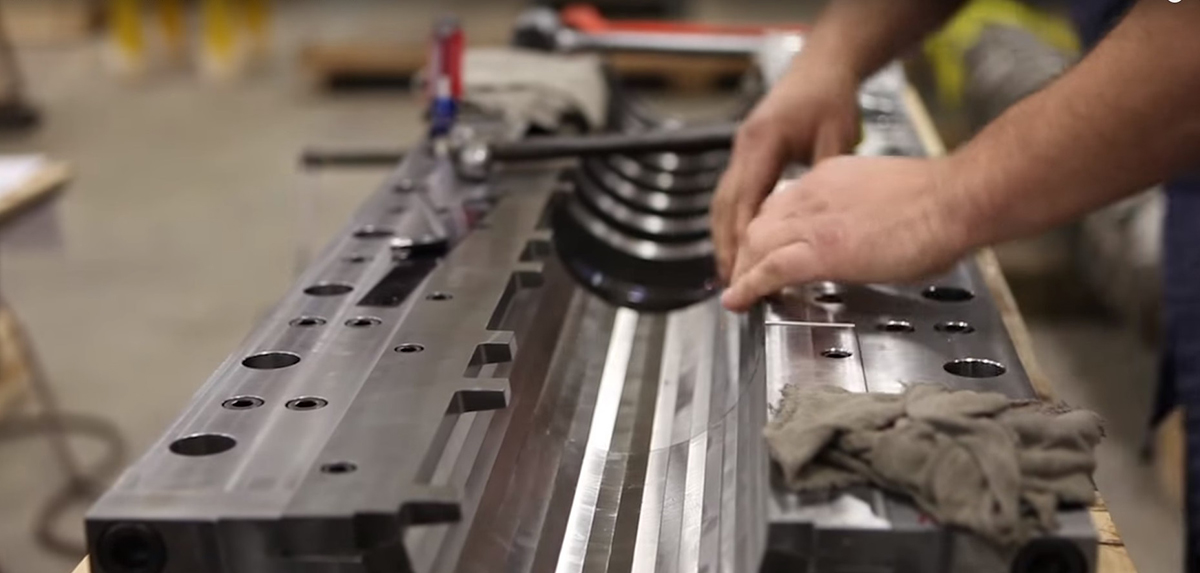

A typical barrel is composed of two 180-degree half circles, each containing numerous bars and metal spacers depending on the manufacturer and the machine’s size. In the smallest Anderson Expeller six-inch diameter machine, for example, five sections make up the barrel. In each section, thirty-four bars make up the circumference, and three metal spacers sit between each bar to create gaps for drainage.

The spacing between bars varies along the length of the machine. The inlet section, or the feed hopper, tends to have the largest spacing between bars, about 20 thousandths of an inch. As more pressure is introduced moving from the inlet to the discharge, spacers need to be tightened to limit the number of solids coming out with the oil flow. In the middle of the barrel, spacing is reduced to around 15 thousandths of an inch, and at discharge, pressure is at its highest, and spacing sits at about 10 thousandths of an inch.

This is a good starting point for a barrel’s initial spacing, but it is likely not the end-all-be-all solution. Seeds are highly variable materials, and depending on upstream preparation, it will impact how the liquid separates from the solids. A strong performing facility will know how to look for signs of an issue with barrel spacing and adjust accordingly.

Need assistance with your oilseed equipment now?

Do not hesitate to call us at 1(800) 336-4730 or use our contact form.

How to know when you have a problem

A visual inspection of the drainage cage can often provide enough information to know if your barrel is spaced correctly. As the machine is running, oil should be flowing out of the drainage cage. If the oil is not coming out quickly enough, it may be time to open up the spacing. If a stream of solids, not just oil, is extruding between the barrel bars, then it is time to tighten up spacing.

A more precise measurement method can be determined by collecting the oil coming out of the machine, letting it settle, and weighing the solids. The ideal measurement is 10-15% solids by weight. A common misconception is that these solids, commonly known as foots, in the final product are bad. In fact, getting some solids is a good thing, and it indicates that your press is applying enough pressure. These fines will be recycled during the oil clarification process.

The importance of expert advice

A properly spaced barrel will produce a high-quality product and ensure maximum efficiency in your screw press. A one-size-fits-all approach to spacing can end up costing your business in the long run if you reduce capacity and overall production or increase the solids that need to be removed downstream. Your team needs to be equipped to space your barrel properly and monitor it for efficiency. Our process engineers develop standard operating procedures for each system and can provide on-site operational training for your production team. By working with an Anderson expert, you can increase the efficiency of your plant and ultimately save time and money.

To speak with an Anderson expert, use our contact form here.