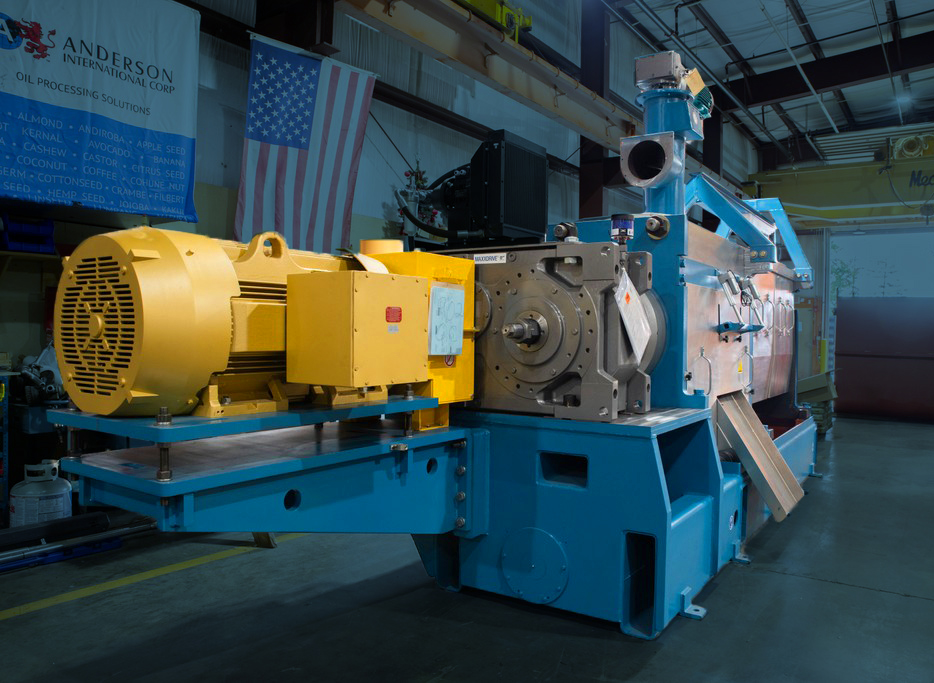

Since its inception in 1888, Anderson has been a pioneer in seed oil processing technology. For over a century, we have consistently demonstrated a commitment to invent and innovate, developing groundbreaking solutions that have shaped the industry. This rich legacy, spanning 135 years, is now further advanced with the introduction of the Lion Series Expeller®.

This latest line of oil press machines represents the pinnacle of Anderson’s expertise, building directly on the extensive knowledge and engineering excellence cultivated over generations. The Lion Series embodies our enduring dedication to providing cutting-edge technology and reliable performance for seed oil producers worldwide.

What sets the Lion Expeller Oil Press apart? How is it different from our other equipment? This blog post will explore the answers to these questions.

Key features

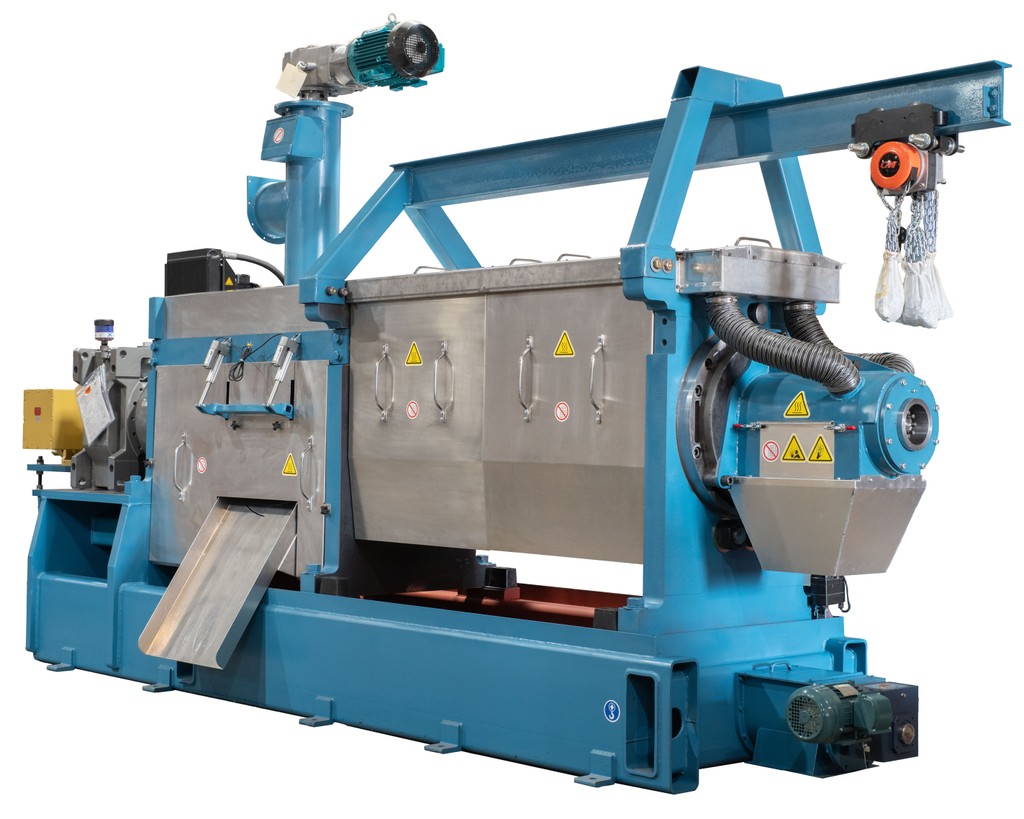

The versatile Lion Series offers a comprehensive solution for various industrial applications, available in three distinct sizes: the compact 600, the mid-range 1200, and the robust 1600. Each model is meticulously engineered to excel in critical processes such as pre-pressing, and post extrusion pressing, ensuring optimal performance and efficiency across the board. (Note: The 600 and 1200 models are currently in operation while the 1600 is expected to reach production floors in Q1 2026.)

The Lion Series oil presses are engineered with several key features that enhance performance, maintenance, and adaptability, making them an optimal choice for oilseed processing.

Gearbox design

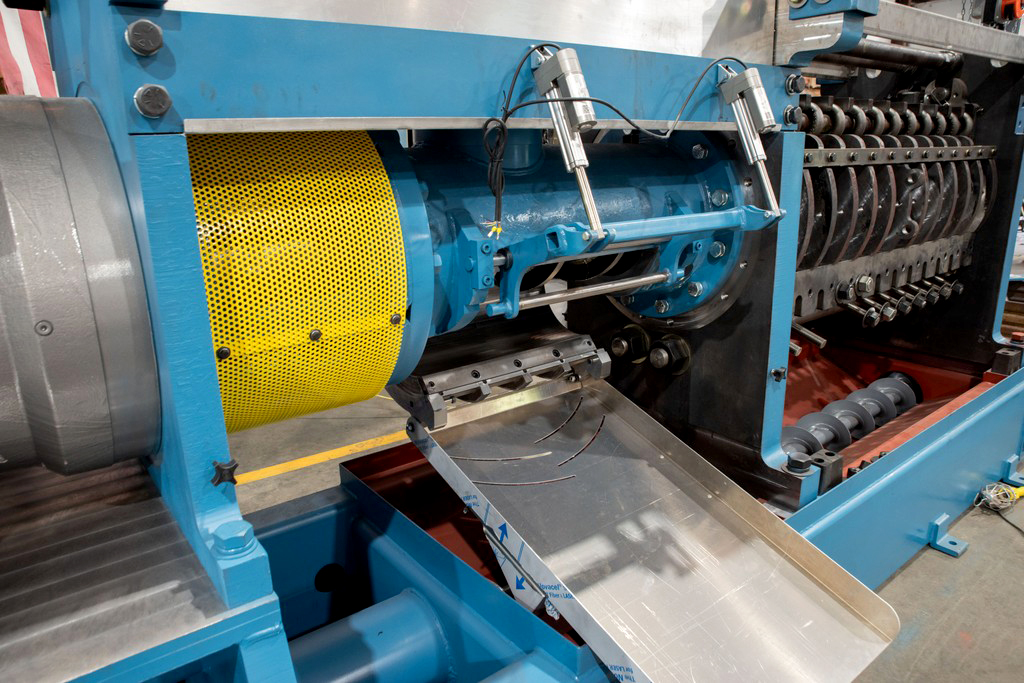

At the heart of the Lion Series is a robust helical gearbox, which comes standard off-the-shelf. Helical gearboxes are ideal for high-speed, high-torque applications due to their smoother, quieter operation, higher load capacity, gradual tooth engagement, and efficient power transmission, even between non-parallel shafts. This gearbox is designed for reversibility, which simplifies clearing jams and allows operators to quickly address any issues that may arise during production.

Maintenance features

The Lion Series also incorporates hinged barrel cages, crucial for reducing maintenance downtime. These hinged designs allow easy access to internal components, streamlining routine inspections and repairs. Additionally, the optional removable maintenance “I” beam allows for even greater ease of access during servicing. As a result, operators can conduct maintenance tasks quickly and efficiently, minimizing production interruption and enhancing overall profitability.

Performance enhancements

The adjustable choke mechanism is another significant feature of the Lion Series. This feature empowers operators to fine-tune oil extraction processes, adapting to varying oilseed types and market demands. Operators can enhance oil extraction efficiency by optimizing the choke setting and ultimately increase yield, making the Lion Series highly versatile and responsive to changing production needs. The integration of Anderson’s Diamonbar® barrel bars, alongside new barrel lining and clamping technology, ensures durability and efficiency in the extraction process. The automatic release hopper system also improves operational flow and minimizes manual intervention, allowing smoother transitions during feeding and processing.

Equipment durability

The Lion Series incorporates Anderson’s cutting-edge metallurgical hardening techniques, setting a new standard for machinery durability. This advanced process significantly reduces wear and tear, ensuring unparalleled longevity and minimizing the need for frequent maintenance. As a result, businesses can experience maximized uptime, increasing their operations’ productivity and efficiency.

Automatic Release Hopper System

Performance insights

Each oil press machine of the Lion Series is designed to meet the capacity requirements of your organization.

PERFORMANCE RATING (Based on Extruded Soy)

| Model | Connected HP | Capacity (MTPD) | Residual Oil |

| Lion-600 | 75-100 | 50-60 | 5-7% |

| Lion-1200 | 300-400 | 130-150 | 5-7% |

| Lion-1600 | 600-800 | 300-400 | 5-7% |

PERFORMANCE RATING (Based on Pre-pressing soft seeds)

| Model | Connected HP | Capacity (MTPD) | Residual Oil |

| Lion-1200 | 300-400 | 300-400 | 18-20% |

| Lion-1600 | 600-800 | 600-800 | 18-20% |

The Anderson Lion Expeller oil press offers exceptional adaptability, transitioning between various oilseed applications with minimal modifications. This flexibility allows producers to respond effectively to market shifts and fluctuations. It boasts an impressive capacity of up to 300 metric tons per day (MTPD) in a single machine (1600 model), achieving residual levels as low as 5% when integrated with Anderson’s extrusion technology.

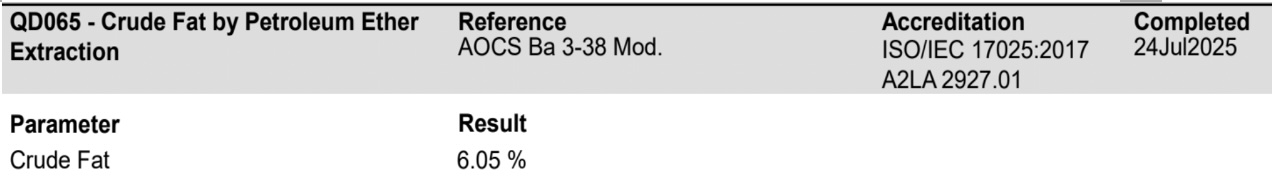

Recent lab tests showcase the Lion Series’ exceptional performance. Operating at six tons (of soybeans) per hour, it achieved an impressive 6.0% residual oil in the meal, demonstrating superior efficiency and yield for your production needs.

Screenshot of recent lab results.

Applications

The Lion Series is well-suited to a variety of nuts and oilseed applications, including:

- Soybean

- Canola/Rapeseed

- Sunflower

- Cottonseed

- Peanuts/Ground Nuts

The Anderson Lion Expeller oil press offers exceptional versatility, making it ideal for processing various oilseeds. Each machine’s design allows seamless transitions between different applications with only minor adjustments, optimizing efficiency and throughput for diverse production needs.

Discover the future of seed oil extraction

Staying ahead of trends and challenges is crucial as the oilseed industry evolves. At Anderson, we pride ourselves on delivering quality, innovation, and unmatched customer support. The Lion Series oil press machines are cutting-edge solutions that can enhance your operations, helping you meet the increasing demands for sustainability and efficiency in oil extraction.

Reach out for a personalized consultation or a demo to see firsthand how Anderson’s equipment can transform your business. Join the ranks of our long-standing customers — many of whom have relied on the same Anderson equipment since the 1920s — and experience the commitment to quality and customer support that sets us apart.