What’s Inside the eBook

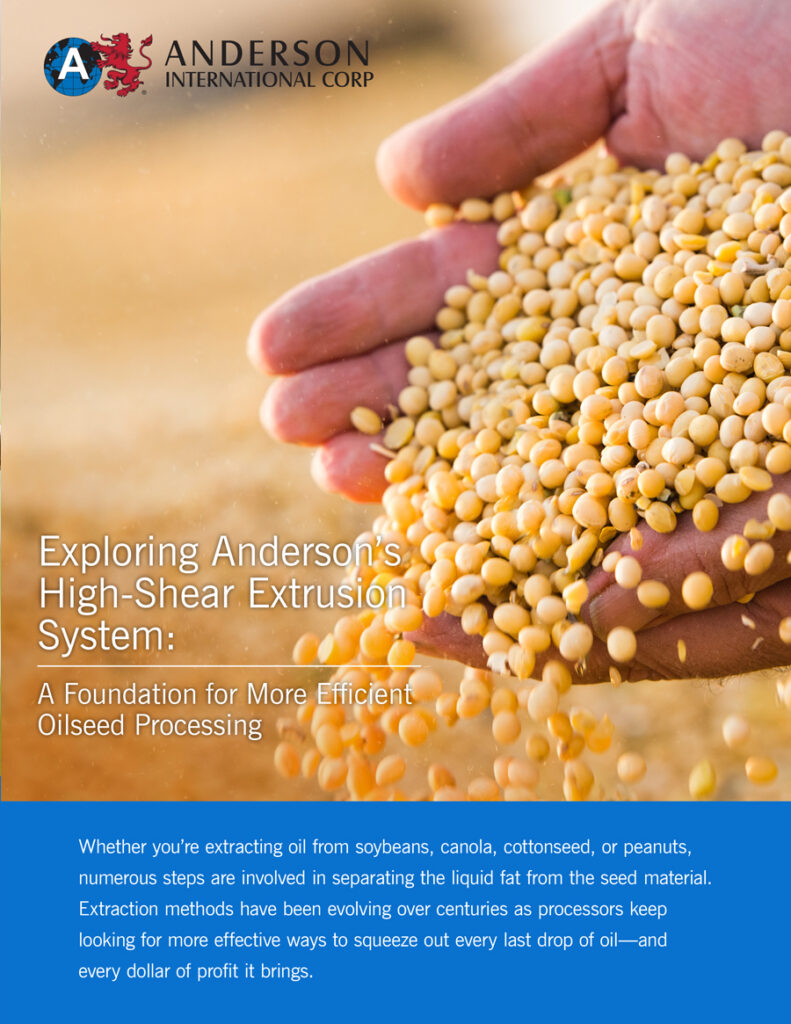

In this guide to high-shear extrusion, we’ll explore how Anderson International’s Dox™ Extruder simplifies oilseed processing, reduces costs, and boosts efficiency through a cleaner, chemical-free system.

The Anderson Dox™ Extruder, which stands for Dry Oilseed eXtrusion, streamlines this process to offer a more efficient solution. A high-shear dry extruder like the Anderson Dox™ combines multiple steps into one multi-functional machine to simplify oilseed preparation and improve the efficiency of the downstream press.

By generating mechanical heat through friction, the Dox shaves the total cooking time from about 20 minutes to approximately 20 seconds. This rapid cooking process minimizes the potential degradation of protein inside the oilseed, protecting the quality of the byproducts while also promoting more efficient oil recovery, with residuals below 6%.

By eliminating the need for steam heat, processors bypass the need to maintain an expensive industrial boiler system, which comes with its own costs, complications, safety concerns, and specialized labor demands. Because the extruder only uses electrical energy, processors can use clean, renewable energy sources like solar, wind, or hydro to power their plants instead of burning fuel.