Although the screw press tends to steal the spotlight as the ultimate workhorse in an oilseed processing plant, charged with the crucial task of separating liquid oil from solid meal, not even the highest-quality press will perfectly separate every particle. Pressed oil will inevitably contain a certain amount of solid residues known as foots. Recovering this sediment downstream is critical to maximizing oil yield and quality—and that’s where the oil screening tank shines as a vital component of any oil mill.

As an essential first step of oil clarification after pressing, the oil screening process not only removes sediment to enhance the purity of the oil, but it also serves other key functions that help a processing plant maximize profits and product quality without adding additional costs.

Recovering oilseed residues after pressing

At first glance, the solid residues that exit the expeller along with pressed oil may seem inefficient, but footing actually confirms that your press is running correctly. Ideally, pressed oil should contain between 10-15% solids by weight. Less than that could indicate that the press isn’t generating enough pressure to thoroughly squeeze the oilseeds, and excessive footing could signal that the drainage gaps in your press need to be adjusted or replaced.

The sediments that remain in oil after pressing can range in size from just a few microns wide to large fist-sized clumps of oil-soaked meal. As normal as they are, these foots must be removed to ensure the oil’s purity. However, since these solids contain at least 50% oil by weight, discarding them would be like throwing money down the drain.

Some plants put their operators to work shoveling these fines out of the oil trough to avoid pumping solids directly into a screener, which would inevitably clog the pump. This unnecessary—and messy—manual labor adds operating costs and headaches that can easily be minimized by simply installing an oil screening tank instead.

Maximizing efficiencies with an oil screening tank

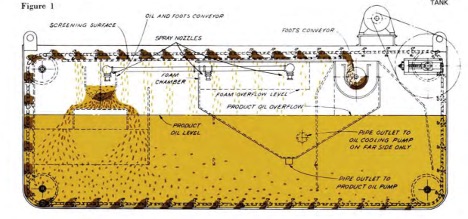

Anderson’s oil screening tank is a highly efficient way to remove most solid residues from pressed oil. Oil and foots that escape the expeller’s drainage cage are conveyed directly into a screening tank located underground beneath the press to avoid pumping the product and risking clogs.

The oil screening tank is essentially a large settling tank where gravity forces solids to settle at the bottom within 45 to 50 minutes. Continuously rotating paddles scrape these settled foots from the bottom of the tank, then drag them across a mesh wire screen at the top of the tank, allowing oil to drain back down as the solids are conveyed back into the press.

This primary screening process removes up to 70% of solid residues from the oil, which then heads toward a secondary clarification step where a pressure leaf filter or decanter centrifuge will remove the remaining fines. Since larger foots have already been removed in the oil screening tank, the filters and decanters downstream can work more efficiently. In fact, screening as a first step increases the capacity of secondary clarification equipment, reducing the frequency at which filters must be cleaned or replaced.

The screening tank creates a critical recycling loop by feeding recovered foots back into the press to squeeze out every last drop of oil—and profits. Although it’s one of the simplest machines in an oilseed processing plant, driven by a modest one-horsepower motor, an oil screening tank pays for itself within months by recouping extra profits through recovered oil—without adding additional energy costs or maintenance requirements.

Multiplying the benefits of the oil screening process

Although Anderson’s oil screening tank is primarily designed for efficient sediment separation, that’s not the only job this machine performs in a plant. The screening tank also doubles as an oil cooling supply tank.

After the solids have settled, clean oil is continuously drawn from the oil screening tank into heat exchangers that cool the oil, then pump it over the barrels of the expeller press to help control the temperature. The cooling oil flows over the barrels and combines with freshly pressed oil before gravitating back into the drainage bed. The combined oil, along with any residual foots, re-enters the oil screening tank again, and the screening process repeats.

Acting as a combination foots settling tank and an oil cooling supply tank, Anderson’s oil screening tank is engineered to be a rugged, robust piece of equipment built to keep repeating this screening process daily with minimal maintenance—saving costs and countless headaches over time. In fact, one of our customers has been running the same oil screening tank for over 60 years without touching the machine once.

By squeezing every ounce of oil and profit possible from the residues that escape through the drainage cage of your press, the almighty oil screening tank is a no-brainer addition to any oilseed processing plant.

Ready to clarify oil the easy way without adding costs? Contact Anderson International for a customized quote on an oil screening tank.