What’s Inside the eBook

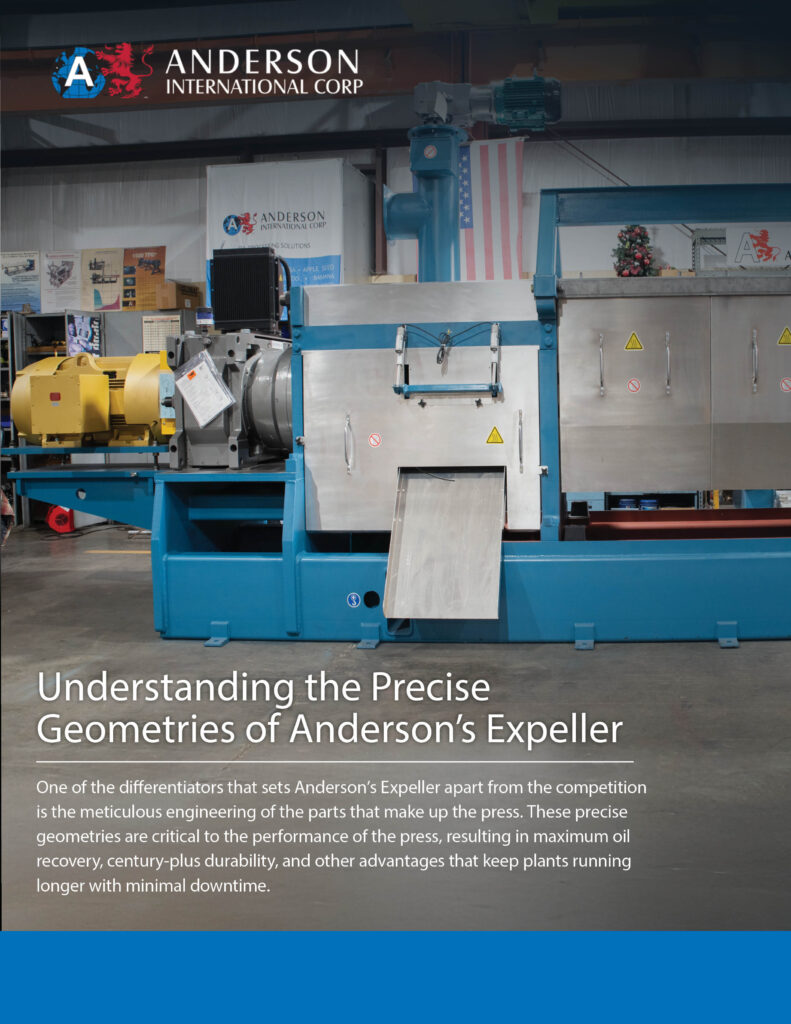

In this guide, we’ll explain how the geometries of various components, like the main shaft and drainage barrel, impact your oilseed processing operation.

Mechanical screw presses are powered by an electric motor, coupled with a gearbox and a thrust unit to form the drive section that keeps the machine running. Power from the motor is transmitted through a gear reducer attached to the main shaft, physically rotating the screw to propel seed material through the barrel.

Anderson’s initial versions of the Expeller used a continuous screw with uninterrupted blades or “flighting” wrapped around the shaft, similar to a standard screw design. But he quickly realized that continuous screws generated so much pressure that the drainage barrel couldn’t support the load, reducing oil yields.

The main worm shaft is encased inside the drainage barrel assembly, also known as the barrel cage or drainage cage. The barrel is intricately designed to allow pressed oil to drain out while keeping solid seed materials inside until the cake is expelled from the discharge end of the machine through the choke.