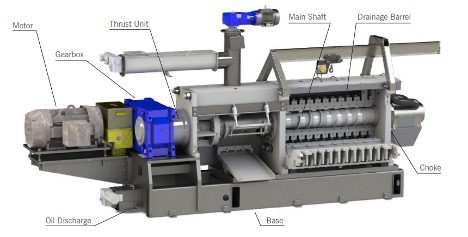

In previous blogs, we’ve described Anderson’s invention of the first continuous screw press design, which revolutionized the oilseed processing industry. But to really explain what makes Anderson’s Oil Expeller so groundbreaking, we need to take a closer look at the meticulous engineering inside the machine. The precise geometries and tight tolerances of each part are critical to the overall performance of the press—and key to the Expeller’s industry-leading reputation.

In fact, the power and precision of Anderson’s equipment boils down to dimensions as small as five-thousandths of an inch—thinner than a strand of hair! Yet these tiny measurements make a big difference when engineering heavy-duty parts designed to handle intense pressures that could theoretically crush a car. This keen machining expertise results in maximum oil recovery, century-plus durability, and other advantages that keep Anderson’s Expellers running with minimal downtime.

Understanding how Expeller parts are engineered to precise specifications can help press operators run their machines effectively and maintain them properly to optimize performance. Get ready for a lesson in basic engineering as we explain how the geometries behind Anderson’s screw press design can benefit your oilseed processing operation.

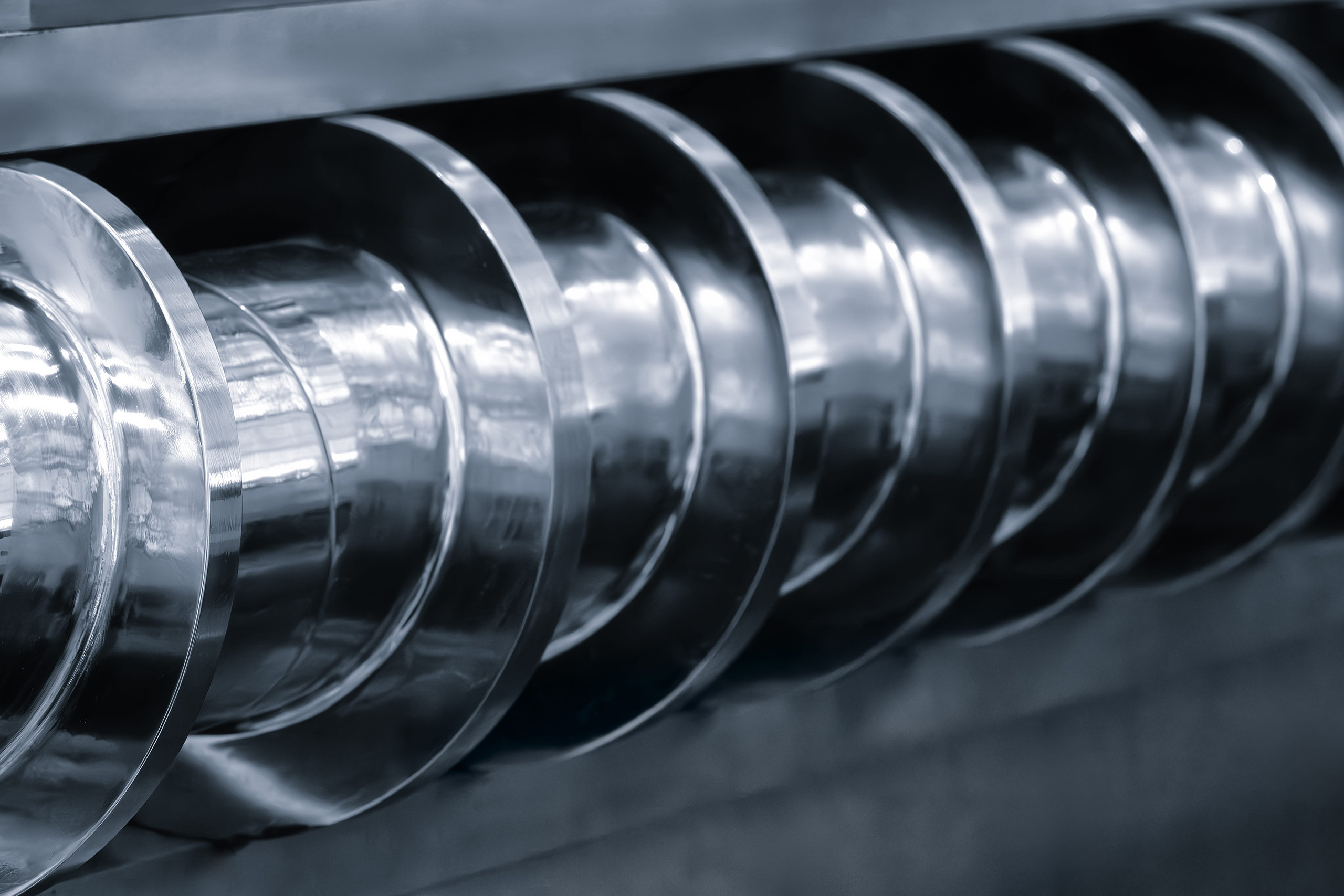

Precise worm flighting

Think of the oil expeller as a super-sized industrial juicer that crushes seeds to separate the liquid fat from the solid meal. A rotating screw, powered by an engine, pushes seed material through the press. Precisely carved worm flights are wrapped around the shaft, pulverizing the seeds to release the oil trapped inside while propelling the product forward under increasing pressure.

The innovative design of these worm flights is a distinguishing mark of the screw press. When Anderson’s founder, Valerius D. Anderson, originally invented the continuous screw press, he used a continuous screw with uninterrupted flighting wrapped all the way around the worm shaft, like a typical screw you’d use to build a deck. But he quickly realized that the continuous screw design generated too much continuous pressure inside the barrel, leading to lower performance.

So, Mr. Anderson modified the design by adding interruptions or gaps in the flight spiraling around the shaft. These interruptions created breaks in the pressure zones inside the barrel, allowing seed material to redistribute and recompress. This lets the press squeeze then release, then squeeze even harder to release even more oil, like wringing out a wet rag with multiple twists to expel as much liquid as possible.

Each worm segment is strategically designed to break apart the seed material while pushing it through the barrel. As the product enters the oil expeller, it comes into contact with the knife edge of the first worm segment, which is angled like a blade to cut into the seed. As the shaft rotates, the wrap and pitch of the worm force the material through the barrel, toward the blunt edge of the first flighting and, ultimately, toward the knife edge of the next segment.

These worm flights are wrapped around the shaft at specific angles and precise dimensions to optimize the cutting action and to keep material moving continuously through the oil expeller, minimizing jams and backflow to maximize oil extraction.

Also read: Gearbox FAQ: A Closer Look at Screw Press Gearboxes

Durable barrel assembly

If the main worm shaft is the spinning blade inside a super-sized juicer that pulverizes seeds, then the drainage cage is like a massive strainer that catches the solid seed pulp but lets the liquid oil flow free through tiny perforations. For this process to work efficiently, resulting in clean separation of the oil from the meal, every part of the screw press design needs to fit together perfectly.

To ensure that the shaft fits snugly inside the drainage cage or barrel, creating the pressure needed to compress the seeds thoroughly, Anderson machines both components to incredibly tight tolerances, meaning the dimensions are precise to within five-thousandths (0.005) of an inch.

If the cage were too big, the oil expeller wouldn’t be able to generate enough pressure for maximum extraction. If the shaft were too big, the worm flighting would scrape against the inside of the barrel as it rotated, causing instant damage and expensive downtime to repair. The shaft geometry and the barrel geometry must match exactly to ensure the optimal performance of the press.

The inside of the screw press’s drainage cage is lined with barrel bars designed to be removed and replaced as they wear, saving operators from the hassle and expense of replacing the entire steel frame of the barrel. Each barrel bar lining the inside of the cage is surrounded by spacers, creating gaps large enough to let oil flow out, but small enough to retain the solids, which are discharged from the end of the machine through the choke. These spacers are precisely sized to maximize oil recovery while minimizing solid residues in the oil.

Also read: The Advantages of Screw Press Subassemblies

The value of Anderson’s screw press design

The walls of the steel barrel are more than 2.5 times thicker than the inner diameter of the barrel, designed to withstand the intense pressure generated by the screw press due to its design. This durable construction is why Expellers from the 1920s are still in operation today, running longer than many of Anderson’s competitors have even been in business.

When properly maintained, Anderson’s precisely engineered parts last longer between repairs and replacements than other models. Regularly maintaining the wearing components inside the drainage cage can extend the life of the barrel, maximizing your capital investment in the Expeller while lowering the overall cost of ownership.

Also read: Choose Anderson for Your Expeller Press Machine Rebuild

Anderson’s Expeller parts are machined to incredibly tight tolerances and precise geometries, resulting in durable equipment that outlasts the competition (and even outlives many operators by enduring through the generations). Our exacting standards aren’t just engineering technicalities—they’re the key to making equipment more reliable and profitable for press operators.

To dive even deeper into the geometries behind Anderson’s screw press design to see how these details benefit your operation, download our latest guide.