When most oilseed processors talk about extraction—whether using mechanical equipment to physically crush seeds or employing solvent extraction to dissolve them chemically—they’re referring to the specific moment when the oil is separated from the seed. But the truth is that extraction is just one piece of the puzzle. Every step in the process determines the ultimate efficiency of any extraction method, and any variation in these upstream steps can lead to preparation defects that must be counteracted downstream to maximize oil recovery while minimizing operational costs.

In previous blogs, we’ve discussed how pre-treatment steps can impact the operation of mechanical extraction equipment like Extruders and Expellers. Similarly, solvent extraction requires its own set of important pre-treatment steps before seed material can be efficiently extracted. If these conditions aren’t precisely met, processors could face a plethora of preparation defects and process variations that could derail their oil recovery rates along with their profit margins.

In a perfect world, each oilseed processing step would proceed as smoothly as clockwork. But as with any production process impacted by multiple variables, nothing’s ever perfect, whether because of imperfections in a batch of raw material, slight differences in the machine settings under each operator, or variations in the seed temperature and moisture level at any stage during processing. Each of these fluctuations can interfere with oil extraction.

As complex and variable as solvent extraction can be, there’s a simple solution to help processors mitigate these preparation defects to optimize oil recovery.

Oilseed preparation for solvent extraction

Just as seeds must be pre-treated before heading into a mechanical press, raw material must be prepared for optimal processing before solvent extraction begins. These two extraction methods share many of the same pre-treatment steps.

Common seed preparation for solvent extraction includes:

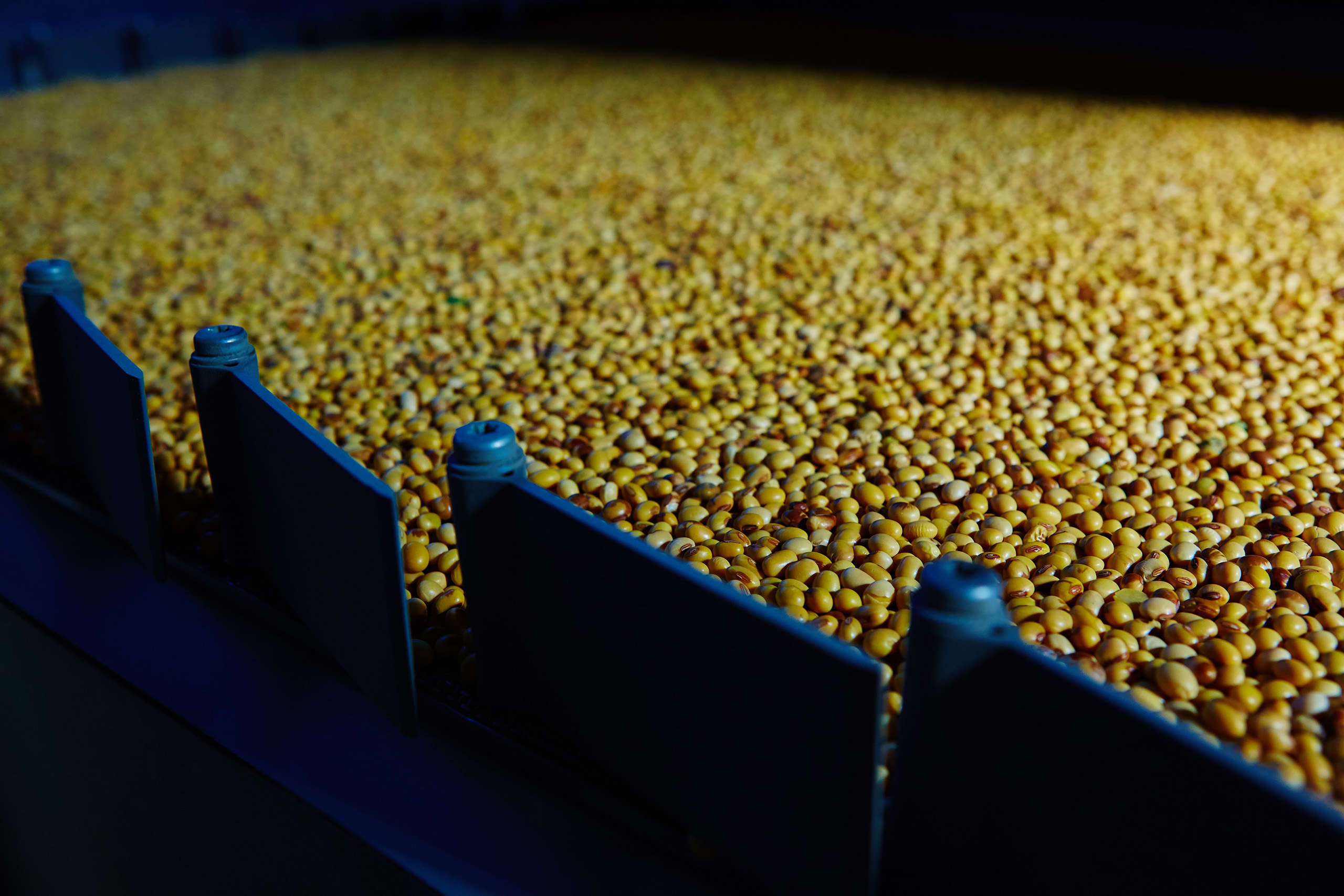

1. Seed cleaning: Removing foreign matter such as sticks, stones, weed seeds, metal, and other debris ensures you only feed your extractor with clean, oil-rich material. Non-seed objects can degrade the quality of your oil, and even absorb oil and solvent during processing, reducing total yields and increasing solvent costs. Abrasive materials can also damage equipment, creating expensive maintenance issues. The goal is to reduce foreign material to less than 1% of the total batch weight.

Cleaning equipment includes magnetic separators to remove metal pieces, screens and aspirators to separate lightweight sticks, seed pods, sand, and soil particles, and destoners to filter out rocks using gravity separation.

2. Cracking and dehulling: Most seeds are protected by an outer shell, or hull, that contains very little fat or protein. These hulls comprise about 6-8% of the total weight of soybeans, for example, and up to 30% of the weight of sunflower seeds. By dehulling or removing at least 90% of these protective coverings, which can absorb fat during processing and dilute the protein content in the meal, processors can improve oil yields and increase protein concentration in the meal.

Typically, roller mills or hammer mills are used to crack thickly hulled seeds apart, then the lighter-weight hulls are blown away by an aspirator.

3. Conditioning: After cracking and dehulling, most seeds are heated or cooked to soften the material for processing. Conditioning is a critical step in adjusting both the temperature and the moisture level of the seeds, releasing the oil to flow more freely in the extractor and softening the seed prior to flaking. Ideally, conditioned seed material should reach a temperature of about 60-70 degrees Celsius with a moisture content of about 10%.

Steam-jacketed conditioners or cookers are traditionally used for heat treatment.

4. Flaking: Oilseeds like soybeans are generally flaked before solvent extraction, creating thin, flat pieces that increase the surface area exposed to the solvent. Ideally, these flakes should uniformly measure about 0.2 to 0.3 mm thick.

Similar to the cracking step, a flaking mill uses large rollers that flatten the seeds, breaking them into smaller pieces.

Finally, flaked seed material is washed with hot solvent, typically hexane, to dissolve the oil. This combination of oil and solvent, known as miscella, separates from the solid meal, which contains some solvent, forming a mixture known as the marc. The marc and miscella undergo further heat treatment to evaporate the remaining solvent from the finished products.

Each of these pre-treatment steps plays a critical part in the overall efficiency of the solvent extraction process, impacting the rate of oil recovery, the quality of the resulting oil and meal, and the costs involved in refining the products at the end of the process.

Identifying preparation defects

Variations in any of these pre-treatment steps can lead to preparation defects that can reduce oil recovery by preventing the flow of solvent, clogging extraction equipment, or reducing the extractable oil content in the seeds. For example:

- High concentrations of foreign material can clog the flow of solvent, leaving oil trapped in the meal.

- Excessive hulls remaining in the material can absorb solvent but yield little oil, reducing overall oil recovery while increasing solvent use (and costs).

- Overly wet seeds (above 12% moisture content) obstruct solvent penetration because hexane is repelled by water, leaving oil trapped.

- Overly dry seeds (below 8% moisture content) will likely crumble into fine particles, which can clog extractor beds and reduce solvent flow.

- Overheating (above 70-80 degrees Celsius) can scorch the material, denature proteins, and degrade the quality of the meal while binding oil to the seeds, which reduces extractability.

- Inconsistent cracking and flaking can create unevenly sized pieces that limit solvent penetration, leaving oil trapped in the seeds.

To analyze the preparation defects that might limit the efficiency of solvent extraction, most processors use a standard laboratory method called Soxhlet extraction to analyze the oil content of seeds throughout the process. This involves collecting a small thimble-sized sample of seed material at various preparation steps and extracting oil from each sample in a flask full of solvent through a repeated cycle of distillation. By comparing oil content across samples, this test helps identify preparation defects and inconsistencies at each point of the pre-treatment process.

Of course, a better way to prepare seed for more consistent, efficient solvent extraction is to add one more pre-treatment step that mitigates all these variations.

Mitigating preparation defects with expansion

Although oilseed processors have traditionally preferred flaked soybean for solvent extraction, flakes are not without their imperfections. Uneven flakes can interrupt the flow of solvent, and overly fine particles can clog the flow altogether, leaving valuable oil trapped inside the seeds.

To solve this problem, while mitigating many preparation defects that can hinder solvent extraction, processors are adding an Expander to their system upstream of the extractor. This innovative process counteracts many of the variations that can impact extraction efficiency, optimizing oil yields along with profits.

Expanders like Anderson’s Solvex™ Expander transform troublesome, non-uniform flakes into a more consistent structure ideal for solvent extraction. Using steam as its primary heat source, the Expander acts as a large pressure cooker, quickly exposing the seed material to a short heat treatment at an elevated pressure.

As the seed material exits the Expander under extreme pressure, the sudden drop to atmospheric pressure causes the injected moisture to instantly evaporate into steam as the product expands, creating a network of sponge-like pores. As the heat escapes and vaporizes, the material solidifies into a dense, porous structure called collets.

Compared to flakes, these collets unlock several benefits for solvent extraction, counteracting many of the preparation defects that plague processors. For example, Expanders improve extraction efficiency by:

- Transforming poor-quality flakes into consistent collets: Flakes require precise upstream preparation—like finely-tuned temperature and moisture levels and perfectly uniform pieces—which is difficult to achieve given the variability of processing. Collets, by comparison, are less sensitive to these preparation defects because the Expander standardizes material with mechanical shearing and quick cooking, creating uniformly dense material for extraction.

- Reducing solvent exposure: Solvent flows more easily through porous collets than around inconsistent flakes, which can compact and shift during extraction, causing channeling that allows solvent to bypass material, leaving oil behind. Effective drainage reduces the amount of hexane required to flood the seed material during extraction, saving processors from costly solvent expenses.

- Reducing solvent retention: The porous structure of collets improves solvent drainage compared to flakes, which tend to retain more solvent and increase the amount of heat required downstream to recover held-up hexane. The Solvex™ Expander reduces solvent hold-up in the marc by 40% and by 20% in the miscella, saving costs in the downstream steps required to remove excess hexane after extraction.

- Increasing extractor capacity: By compressing the material into dense pelletized collets, the Expander increases the capacity of the extractor, allowing more material to be processed. Specifically, the Solvex™ Expander allows the extractor to accept 50% more material without any change in bed depth or residence time. Increased capacity results in reduced energy consumption and decreased operational costs per ton.

- Improving product quality: Whereas temperature and moisture variations upstream can impede solvent extraction efficiency and product quality downstream, the Expander’s short residence time and steam-injected heat treatment control these variable conditions to preserve the quality of both the oil and the meal.

By installing a Solvex™ Expander upstream of the extractor to transform fickle flakes into dense collets, processors can achieve residual oil levels as low as 0.6%, correcting many of the preparation defects that traditionally hinder solvent extraction efficiency.