Since Anderson International invented the first continuous mechanical screw press in 1900, the company has continued improving and innovating its extraction equipment for different applications. After an accidental modification of the Expeller led to the creation of Expanders in the 1950s, this value-added machine made a monumental impact on processing efficiencies across various industries.

Here’s a brief look at the unintended invention of Anderson’s Expander-Extruder-Cooker and how it gradually evolved into the Solvex™ Expander that has become an industry standard in solvent extraction.

The history of the Expander

The Expeller’s unique slotted barrel design allowed liquid oil to effectively drain from solid seed material inside Anderson’s screw press. But one day, a press operator forgot to set the required spacers between the bars in the barrel. With this unintended modification, the plant unknowingly created a solid barrel cage.

When they started running dry processed corn germ through this solid barrel screw press, the operators noticed the corn was popping and swelling as it exited the expeller. The heat generated inside the completely sealed barrel created a pressurized cooking vessel that cooked the corn germ. The starches gelatinized during this process, and when the material discharged from the machine, the sudden drop in pressure caused the corn to explode and expand.

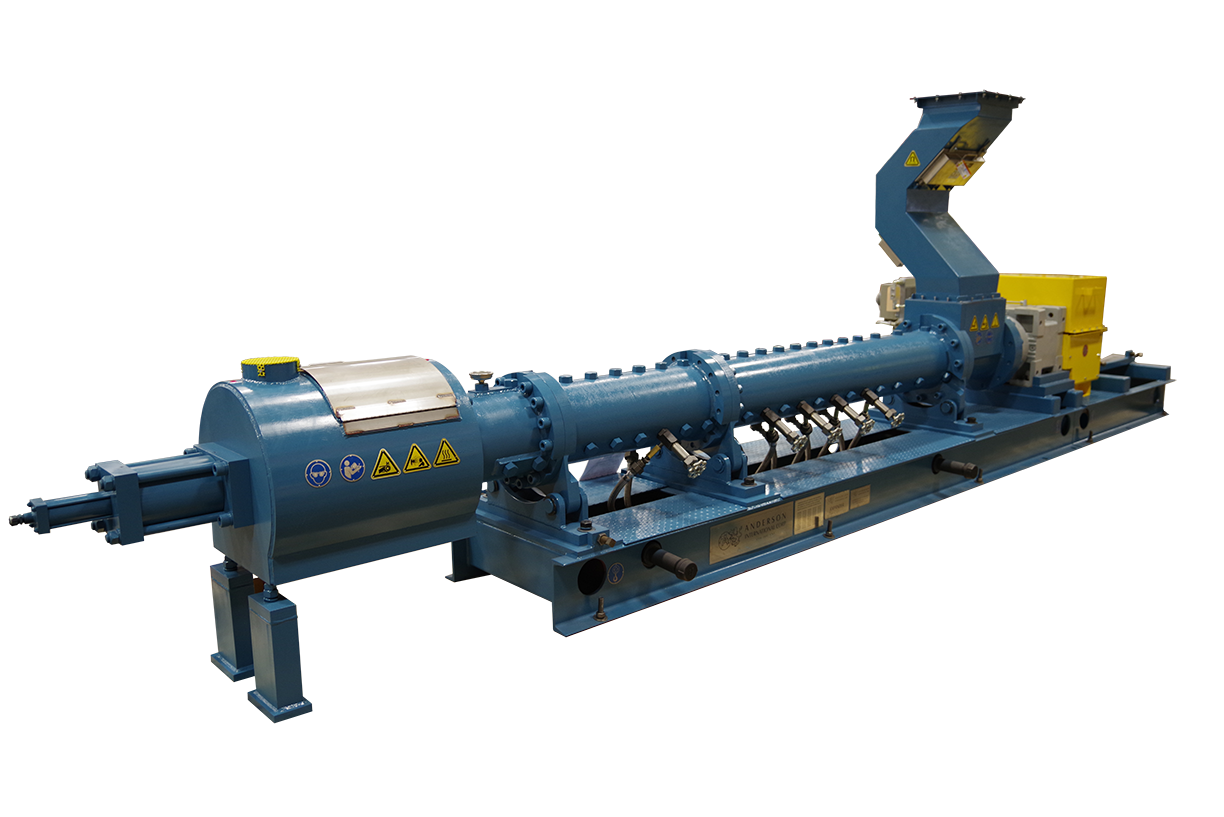

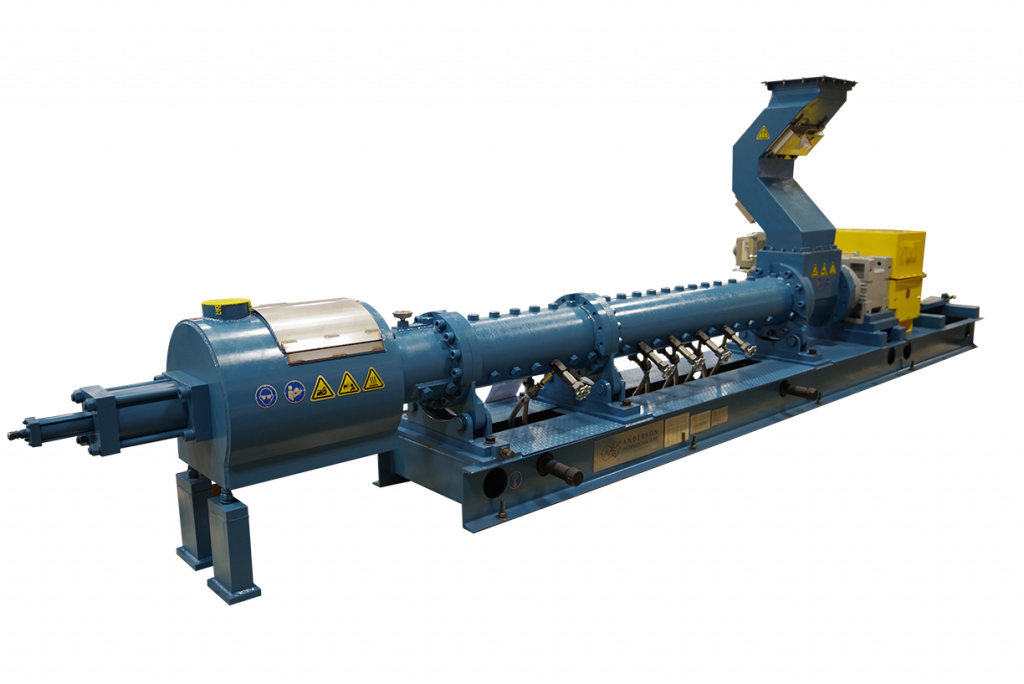

This lucky discovery led to the invention of Anderson’s Expander-Extruder-Cooker™ (EEC), an interrupted flight extruder that cooks grains and vegetable seeds in a pressurized, steam-heated vessel. Steam injection valves add moisture to the material while rotating worm shafts thoroughly knead the mixture together.

This combination of heat, pressure, moisture, and mastication helps rupture the oil cells to prepare the material for extraction while cooking the proteins into a sticky gelatinous glob that adheres together as it exits the extruder. When this gel hits the atmospheric pressure as it’s discharged from the press, the injected water vaporizes, leaving a network of tiny pores that cause the material to swell and inflate. This dense porous structure, known as collets, brings a wide range of processing benefits, especially when it comes to solvent extraction.

Extrusion applications

Since starch was the first ingredient discovered to have this expanding effect, the earliest applications used the EEC to gelatinize starches. Gelatinization occurs when a liquid is dispersed or dissolved into a solid; this happens when starch granules (which are usually too tightly compacted to absorb much water) are placed into boiling water or the conditions inside an Expander cause the granular structure to swell until it bursts and transforms into a gel. Gelatinization brings certain functional characteristics that can be useful for products like paper adhesives and wallpaper paste.

Similar to the gelatinization of starches, expansion also denatures proteins for human and animal consumption—but without damaging the heat-sensitive amino acids they contain. This denaturization can trigger several significant changes, like:

- Deactivating harmful enzymes in the protein, such as urease in soybeans and lipase in rice bran.

- Making difficult-to-digest proteins more easily digestible for humans and animals.

- Improving overall taste and palatability.

These changes revolutionized animal feed processing, bringing Expanders to the forefront of the grain and oilseed industry. At that time, similar solid-barrel extrusion machines were already used in other processing industries. For example, in 1932, Frank B. Anderson received a patent for a solid-barrel screw press used to stuff sausage. While Expanders are technically a type of extruder because the processed material is extracted through a die, Anderson’s pioneering work with vegetable oil extrusion set a new course for the industry.

The high-pressure, high-shear environment inside the Expander accelerated heat transfer throughout the oilseed material, drastically reducing the cooking time to 30 seconds or less. This rapid cook enabled processors to increase capacity while reducing energy consumption and operational costs—ultimately boosting their bottom line.

Because of these advantages, the applications of the EEC expanded to produce dog and cat foods, fish food, and even livestock and poultry feed. Extrusion eventually became essential to creating a range of ready-to-eat convenience foods for humans, from croutons and cereals to TV dinners, cake mixes, and fast food entrees.

Expanding solutions for solvent extraction

Anderson finally spun off the Expander into its own patented standalone machine in 1966. At that time, many of our customers were processing rice bran and running into the same recurring challenges. First, the milling process that removes the outer layer of brown rice, or bran, activates an enzyme called lipase that quickly breaks down fats—forcing processors to race against the clock to extract rice bran oil before it goes rancid. Plus, the fine, powdery texture of the bran made rice even more difficult to process. These challenges severely limited capacity, yields, and profits for processors.

By running rice bran through an Expander, Anderson engineers realized that this technology solved both problems. The high-pressure, high-temperature environment inside the Expander safely stabilizes lipase enzymes and deactivates other anti-nutritional factors while compacting the fine particles into the densely porous material called collets.

It turns out these collets are much more conducive to solvent extraction than the flaked oilseed material that most processors typically used. Solvents like hexane can flow freely through the pores created in the Expander, providing several key benefits like:

- Increased capacity

- The expander compresses material into a greater bulk density, doubling the extractor’s capacity. This efficiency reduces energy consumption and decreases operational costs for processors.

- Reduced solvent exposure

- Solvents can flow more freely and evenly through porous collets than through flakes or pre-pressed meal cakes. This enables fat to dissolve more quickly and drain more effectively, reducing the amount of solvent required for extraction.

- Reduced solvent recovery

- Because less solvent is used in extraction, less energy is needed downstream to recover hexane from the finished product. The Solvex Expander reduces solvent holdup by 40% in solid byproducts and 20% in liquid byproducts.

- Maximum oil recovery

- Expanded collets enable more effective solvent permeation and drainage, allowing processors to extract as much oil as possible. Processors can achieve residual oil levels as low as 0.5% with the Solvex, compared to 1-2% without an Expander.

Because of these benefits, Anderson’s Solvex Expander has become an essential tool in solvent extraction by preparing oilseed material like soybean for more efficient processing.

A legacy of extraction expertise

Over the last seven decades, Anderson has continued to adapt the basic EEC design for various industries—spawning the Solvex line of lightweight carbon steel expanders for feed and grain applications, and a heavy-duty stainless steel version for the mechanical drying of synthetic rubber, dubbed the Expander-Dryer®. These innovations eventually led to the invention of the Dox Extruder, which we’ll cover in our next blog.

With over a century of leadership in the design, manufacture, installation, and operation of oil and feed milling machinery, Anderson has delivered hundreds of Expanders to serve various industries around the world. Customers use our equipment to process everything from aqua feed to pet food, full-fat soy for poultry and pig feed, textured vegetable protein production, and pre-treatment of a range of oilseeds for solvent extraction.

To learn how our Expander line of equipment can expand your plant’s profits and efficiencies, contact Anderson International today.