The “bigger is better” mantra has been touted for centuries, and the oilseed industry is no stranger to it. A few decades ago, processing 10-20 metric tons per day (MTPD) of oilseed was considered sizeable. Now, the average plant processes several hundred tons of oilseed per day.

Enhanced machinery, the use of chemicals, and the introduction of expanders and extruders for seed preparation have spurred this shift in scale.

These advancements have benefitted soy processing, a crop with harvests of 300 million metric tons per year worldwide. But crops like palm kernel, grown at 20 million metric tons per year globally, or copra, less than six million metric tons per year, are rarely processed at such a high capacity.

In addition to limited crop production, the high-fiber makeup of oilseeds like copra and palm kernel makes it challenging to process in large quantities.

But around the globe, the demand for small-batch specialty oils is growing. Market reports project that the specialty fats and oils market will grow at a CAGR of 7.8%, increasing from USD 12.6 billion in 2020 to USD 19.8 billion by 2026.

Small-scale and specialty oilseed processers have good reason to enter the industry, but they have their work cut out for them by working with difficult-to-process seeds in a market currently tailored to mass production.

A small-scale oilseed processing plant should take into account the following factors when selecting machinery.

Selecting the best processing equipment

Solvent extraction is undoubtedly the most efficient method of oil extraction on the market, typically only leaving 1% residuals in the meal. But solvent extraction is expensive, both in capital and operating expenses, and poses risks due to the potential for chemical fires or explosions. It is a complex process and requires a large volume of finished product to outweigh the investment in equipment and time.

The mechanical press is better suited to small-scale oilseed processing because of its simplicity, versatility, and low capital and operating costs. Mechanical extraction also better serves the needs of health-conscious consumers looking for more natural products, who often turn to the specialty seed market for healthier, chemical-free options.

Processors entering the specialty seed market should select an appropriately sized press for its intended use. For a press to run efficiently and keep residuals at the lowest possible levels, their machines must operate at the intended capacity. If the press is oversized for a given material and run rate, there will not be enough internal pressure to squeeze all of the oil from the seeds. When this happens, processors are required to send the material through the press again or risk leaving valuable oil behind. Additional passes reduce efficiency and increase energy use. Presses that are too small for the intended capacity will likely jam, resulting in costly downtime. A properly sized press will maximize efficiency and reduce unnecessary downtime.

One of the biggest challenges for low-capacity processors is that the cost of a press is not linear. A machine engineered to operate at 25 MTPD is not half as expensive as a machine that processes 50 MTPD. A smaller press may only cost 10 percent less than a press that can double capacity. This base investment is disadvantageous for small-scale processors, and they must reduce costs elsewhere to make up for it.

A simple system with minimal machinery can help small-scale processors reduce costs. It is cost-effective for large-scale processors to purchase additional upstream equipment like extruders or steam-heated vessels to reduce oil residuals. But an expensive purchase of additional equipment does not make sense for a small operation. A five percent reduction in residual oil on low volumes of material can’t offset a 20 percent increase in capital expenses.

Less machinery also means less energy usage, a small footprint, and minimal staff requirements to monitor and maintain multiple machines.

The answer for small-scale oilseed processing

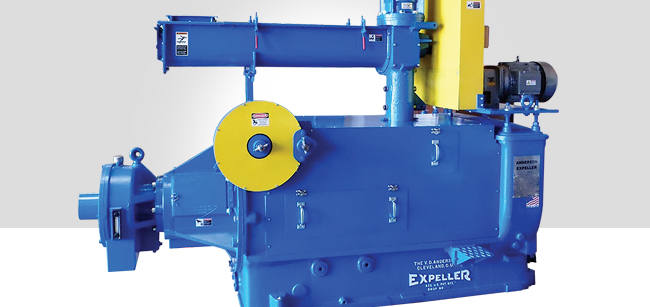

Specialty and hard-to-process oilseed require a high-quality, efficient, simple machine to be profitable. The Anderson Duo™ Series Expeller® is an ideal choice due to its size and functionality for small-scale oilseed processing capacities of 10-30 tons per day.

No press has been used in a wider variety of applications than the Duo, including:

- Almonds

- Avocado pits

- Coffee beans

- Copra

- Corn germ

- Grapeseed

- Hazelnuts

- Hemp seed

- Linseed

- Mustard seed

- Palm Kernel

- Pecans

- Pistachios

- Safflower

- Sesame

- Walnuts

Unlike most presses on the market, the Duo does not require expensive and energy-consuming external heat vessels before pressing. Engineered for torque, the Duo generates tremendous pressure on the product, making up for the lack of pre-treatment.

However, the Duo series has the flexibility to add a steam-heated conditioning vessel if desired by a processor.

Specialty seed processors can benefit from the increased market demand for cold-pressed and more natural products. The Duo has built-in features throughout the barrel, choke, and shaft to provide precise temperature control.

Read more: 4 Factors To Consider With Cold Pressed Oil Processing

Because the Duo operates two pressing sections in tandem on a single machine, it allows for the most efficient use of horsepower to achieve the lowest possible residual oils. It eliminates the need for processors to run the product through a press twice, which is often necessary when processing without heat. The single pass reduces energy costs, time, and labor.

The increased torque, precise temperature control, and single-pass functionalities require the Duo to be built with precision and high-quality steel. The Duo is known for longevity and is an investment that will stand up to the test of time.

Why Anderson

Small-scale and specialty oilseed processors need a machine that can achieve low residuals on the most stubborn material without expensive equipment upstream, a large footprint, or complex chemical requirements. The Duo not only meets these needs, but it provides extreme flexibility through its ability to process a variety of seeds and by allowing hot or cold-pressed operations.

When choosing Anderson, each client receives the full support of the technical service team for continuous process operations and maintenance of their facility. Ongoing support includes operation and maintenance training, engineering design support for project expansion, and dedicated inventory programs for the lifetime of a facility.

For more information about the Duo Expeller Series, contact us here.